vickers hardness test lab manual pdf|hardness tester lab report pdf : tv shopping 1. Scope. 1.1 This test method covers the determination of the Vickers hardness of metallic materials, using applied forces of 1 kgf to 120 kgf,2 the verification of Vickers hardness . WEB9. -5. 6. Mexico - Club Atlético de San Luis - Results, fixtures, squad, statistics, photos, videos and news - Soccerway.

{plog:ftitle_list}

13 de abr. de 2023 · Upon download, SwiftKey lets you set it as your default keyboard on both iOS and Android (the app includes easy-to-follow instructions to help you get there in just a few steps), so you can access it across all your favorite apps, from email apps to social media and more. SwiftKey lets you choose up to five languages to integrate into .

Practical application of engineering skills, combining theory and experience, and use of other relevant knowledge and skills. Analyze a problem, identify, formulate and use the appropriate .

VICKERS HARDNESS TEST Aim: To determine the Vickers hardness of hard materials such as hardened steel and moderately hard materials such as brass, copper and aluminium. Theory: . (I) Aim: To determine the hardness of the given Specimen using Vickers hardness test.

The Vickers hardness test, which measures a material's resistance to deformation under a controlled load, is a commonly used technique to assess .

1. Scope. 1.1 This test method covers the determination of the Vickers hardness of metallic materials, using applied forces of 1 kgf to 120 kgf,2 the verification of Vickers hardness .Vickers hardness should be reported like 800 HV/10, which means a Vickers hardness of 800, was obtained using a 10 kgf force. The advantages of the Vickers hardness test are that .Our advanced Macro Vickers hardness tester 3842 is a state-of-the-art, precise testing system suitable for hardness analysis of metallic specimens in metallography laboratories or .The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .

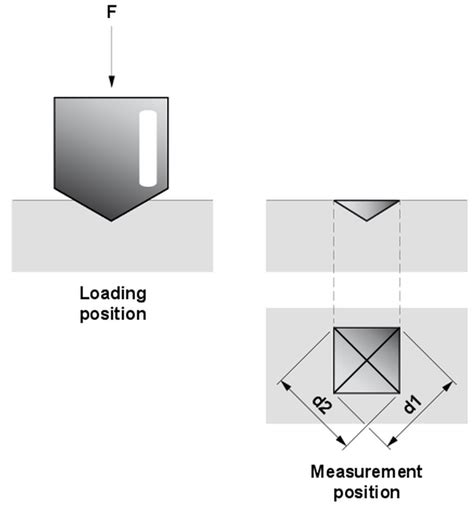

The Vickers hardness test is performed by pressing a diamond indenter tip in the form of a square-based pyramid into the sample at a specific load and then measuring the diagonal .E691 Practice for Conducting an Interlaboratory Study to 3.2.2 microindentation hardness test, n—a hardness test, Determine the Precision of a Test Method 3 normally in the Vickers or Knoop scales, using test forces in 2.2 ISO .

durability can be determined by looking at its Vickers hardness value. The Vickers hardness test, which measures a material's resistance to deformation under a controlled load, is a commonly used technique to assess .

vickers hardness test procedure pdf

vickers hardness test manual

scratch test concrete

Refer to Mechanics of Material Laboratory manual for detail information. Summary of Theory: Vickers hardness test requires a diamond pyramid indenter with an included angle of 136o. This technique is also called a diamond pyramid hardness test (DPH) according to the shape of theand a test-force loading device that lets you set the desired test force! The HM-200 series is ideal for quality control and mechanical characteristic evaluation using Vickers hardness testing of small areas.Download Free PDF. Standard Test Method for Vickers Hardness of Metallic Materials 1 . Laboratory, or Referee Tests, where a high degree of accuracy is required. 1.1.2 Routine Tests, where a somewhat lower degree of accuracy is permissible. 1.2 This standard does not purport to address all of the safety concerns, if any, associated with its .

The Wilson® VH1150 Vickers Series Hardness Testers offer a versatile and user friendly solution for a wide range of hardness scale testing. For single scale hardness testing, the Wilson VH1150 Tester is equipped with a five-position turret which includes one indent-er position as well as a 10x and 20x objective.This part of ISO 6507 specifies the Vickers hardness test method, for the three different ranges of test force for metallic materials (see Table 1). Table 1 — Ranges of test force Ranges of test force, F N Hardness symbol Designation F W 49,03 W HV 5 Vickers hardness test 1,961 u F Low-force Vickers hardness test < 49,03 HV 0,2 to < HV 5Contact ASTM Customer Service at [email protected]. TABLE 4 Vickers Hardness at 1 kgf Test Force (HV 1) Test Block Nominal Hardness (HV) 200 400 800 Average (HV) X̄ 209.2 413.8 812.9 Bias % Repeatability Standard Deviation (HV) sr Reproducibility Standard Deviation (HV) sR Repeatability Limit (HV) r Reproducibility Limit (HV) R N/A N/A N/A 4.1 .

Mechanical hardness testing is fundamental in the evaluation of the mechanical properties of metallic materials due to the fact that the hardness values allow one to determine the wear resistance .The Vickers hardness test method, also referred to as a microhardness test method, is mostly used for small parts, thin sections, or case depth work. The Microhardness test procedure, ASTM E-384, specifies a range of light loads using a diamond indenter to make an indentation.

The FALCON 500 offers a leading technology base for manual, automatic or fully automated testing of Micro and Macro Vickers, Knoop or Brinell assignments. With a wide choices of test force configurations, answering any possible imagination, the FALCON 500 can be completed with fully integrated hardware options to assure a match with the .

The NG-1000 - Micro Vickers and Knoop Hardness tester is the most advanced hardness tester for accurate measurements and ease of use. The NG-1000 - Micro Vickers and Knoop Hardness tester comes standard with a motorized turret and is available in three (3) different configurations to suit all requirements.EXPERIMENT NO. – 01 AIM :- To study the Brinell Hardness testing machine and the Brinell hardness test. APPARATUS: - Brinell Hardness testing machine, specimen of mild steel / cast iron/ non ferrous metals and Brinell microscope. THEORY: - Hardness represents the resistance of material surface to abrasion, scratching and cutting, hardness after gives clear identification .The most commonly used low-load method is Vickers. Low-load hardness testing is mainly used for testing of small parts, thick coatings and materials with low hardness. . DuraScan micro hardness tester Vickers laboratory hardness tester – from manual to fully automatic. Test methods. Vickers; Knoop; Brinell; Test load. 0.00025 – 62.5 kgf .

The ultimate macro-vickers hardness tester is the Wilson VH1150 Macro vickers Hardness Tester. Boasting a unique load range of 300gf – 50kgf, enjoy its user-friendly operation with automatic load selection . Keep your lab up and running with access to wear part kits and your machine being services by one of our highly trained Service .load-dependent. In Table 2 are given the Vickers hardness numbers for a test load of 1 kgf. For obtaining hardness numbers when other test loads are used, the Vickers hardness number obtained from Table 2 is multiplied by the test load in kilograms-force (Table 3). N. ote. 1—The Vickers hardness number is followed by the symbolMicro Vickers Hardness Tester Vickers Hardness Test of Curved Surfaces Vickers hardness is used as an index of the mechanical and physical properties of materials in a variety of fields, including quality control at production sites, research and development, and analysis. A distinctive feature of the Vickers hardness test is its simplicity. Hardness of the samples has been evaluated by using Vickers Hardness Test. The Corrosion behaviour of as-received and thermally oxidised samples have been evaluated by using weight loss method.

A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .

produced by gradual loading. There fore, impact tests are performed to asses shock absorbing capacity of materials subjected to suddenly applied loads. These capabilities are expressed as (i) rupture energy (ii) modulus of rupture and (iii) notch impact strength. Two types of notch impact tests are commonly 1. Charpy test 2. Izod testOverview of hardness testing methods 4 3. Low-load & micro hardness testing machines − the DuraScan Series 6 4. Universal hardness testing machines − the DuraVision Series 8 5. DuraJet Rockwell hardness testing machine – flexible & versatile 10 6. ZHR Rockwell hardness tester 12 7. ecos™ III – The most efficient hardness testing .

The paper reports on IIT at test forces ranging from 0.002 N to 1000 N on non magnetizable steel X8 CrMnN 18- 18 (1.386) with well polished surface using Vickers indenter and four hardness machines of different design (Nano Indenter XP, Fischerscope H 100, Zwick Z005 with Universal hardness head and a laboratory four-column set up materials .LECO Hardness Testing Systems One is Right for You. Advanced features provide you with greater convenience and efficiency. LECO offers a wide selection of hardness testing systems to match any application or budget. Choose from manual and automatic model configurations for Microindentation, Macro-Vickers, Multi-Vickers or Rockwell-type testing.

Lab Manual | Strength of Materials (ME-303) Mechanical Engineering Department Dr. Irshad Ahmad Khan 23 Sagar Institute of Research and Technology, Bhopal Experiment No. 8 AIM: To Conduct the hardness test on Vickers Hardness Tester. OBJECT: To determine the hardness no. of mild steel, carbon steel, brass and aluminum specimens.

At low values (VH<~400HV), Vickers hardness was shown to be the same as Brinell hardness (see hardness conversion section). Schematic representation of the Vickers test is shown in Figure 1. Further information regarding existing standards and procedures can be found in references [1,2]. Vickers hardness formula. The Vickers hardness (HV) is .Micro hardness testing for your laboratory according to Vickers, Knoop and Brinell Load range from 0.00025 to 62.5 kg Inform now and request for quotation!cutting. Mainly there are three types of hardness tests. 1) Indentation test 2) Abrasion or wear test 3) Scratch test. Of these the most important tests are based upon the principles of indentations and are the Brinell's, Rockwell and Vickers's hardness tests. In each case the material under test is indented by another body to which a static .

In Vickers hardness testing, a square pyramidal diamond indenter with specified face angles is used (see figure below). After the pyramidal diamond tip (indenter) is pressed into the test sample at a perdetermined load (F[N]), the indentation on the sample is measured using a microscope.

scratch test cell migration protocol

rockwell hardness tester procedure pdf

web15 de mai. de 2023 · Espaçolaser — Foto: Reprodução/Facebook/Espaçolaser. Mais recente Próxima Queda na demanda faz lucro da Taurus recuar 81,8% no 1º tri, para R$ .

vickers hardness test lab manual pdf|hardness tester lab report pdf